Introduction:

The pharmaceutical industry relies on exceptional quality and consistency to ensure that medicines are safe, reliable, and effective. Chemistry, manufacturing, and controls (CMC) play a crucial role in this process. CMC refers to the scientific, regulatory, and technical procedures involved in developing and manufacturing pharmaceutical products. In this blog post, we will delve into the significance of CMC in the pharmaceutical industry and examine its key contributions.

Understanding Chemistry, Manufacturing, and Controls:

CMC encompasses the entire product life-cycle of pharmaceuticals, from development, clinical trials, and regulatory approval to large-scale commercial manufacturing and post-market surveillance. It involves a comprehensive set of processes, protocols, and quality standards that ensure the consistency, purity, and safety of medical products.

Key Points:

Development and Testing:

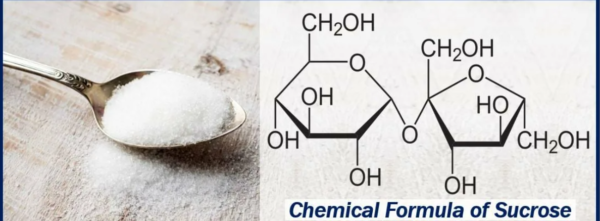

CMC starts with the development and testing of new drug candidates. During the initial phases, key CMC parameters are identified, such as active pharmaceutical ingredients, formulation, stability, and method of manufacture. The quality of the drug candidate is evaluated based on its physicochemical and biological properties, including its safety and efficacy. These parameters serve as the foundation for further development and production.

Regulatory Compliance:

Regulatory compliance is critical in pharmaceutical development and manufacturing. CMC ensures that all medicines are developed, manufactured, and controlled according to current good manufacturing practice (cGMP). cGMP outlines strict regulations and standards that ensure the quality, safety, efficacy, and performance of drugs, including the manufacturing and quality control processes. Regulatory authorities such as the US Food and Drug Administration (FDA) require strict adherence to these guidelines before allowing drugs to be approved for the market.

Manufacturing and Quality Control:

The manufacturing and quality control stages represent the heart of the CMC process. Contract manufacturing organizations (CMOs) are responsible for producing drugs, while quality control (QC) ensures that the drugs meet all regulatory requirements. The QC process includes analytical and microbiological testing and product inspection. The testing evaluates drug purity, strength, stability, and ensures that all manufacturing processes are controlled. Quality control plays a crucial role in preventing contamination, ensuring consistency, and evaluating the shelf-life of finished products.

Post-Market Surveillance:

The CMC process does not end with regulatory approval and commercialization. Ongoing monitoring and surveillance of the product continue both by the regulatory authority and the pharmaceutical company itself. The post-market surveillance continues the evaluation of safety, efficacy, and quality of drugs, which include continuous updating of the product label and evaluating the potential need for additional warnings or labeling changes.

Conclusion:

Chemistry, manufacturing, and controls serve as the backbone of the pharmaceutical industry, ensuring that medicines meet rigorous quality, safety, and efficacy standards. CMC involves a comprehensive set of processes and guidelines that begin with drug development and clinical trials and continue through large-scale commercial production and post-market surveillance. The adherence to CMC guidelines is critical in meeting regulatory compliance, preventing contamination, ensuring consistency and quality of medications, and protecting public health. By maintaining robust CMC processes, we can continue to provide safe, effective, and reliable medical treatments for patients worldwide.

#chemistry #manufacturing #controls